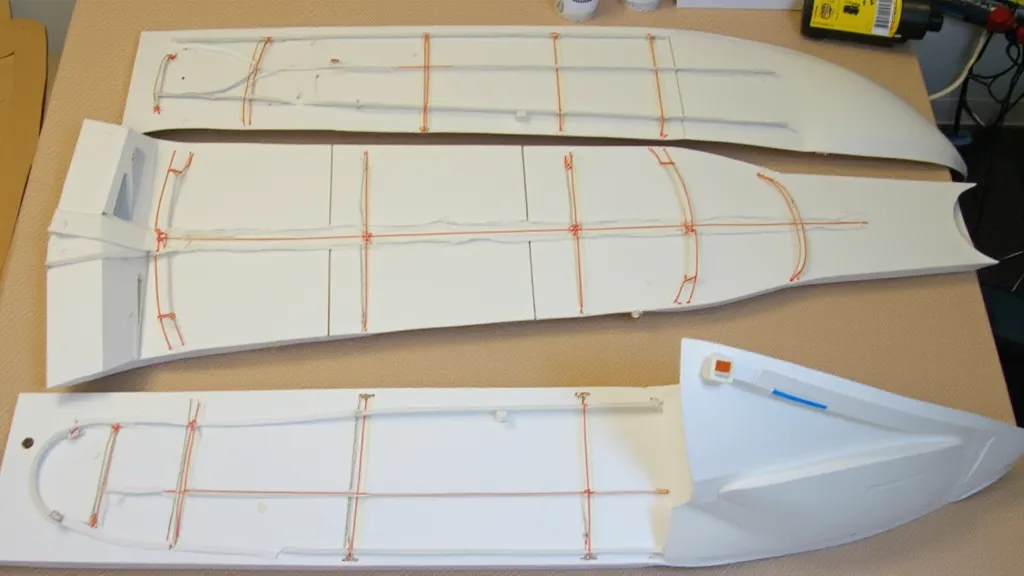

Wing Construction: Ribs, Spars, and Covering

Building the wings of your RC airplane is a critical step, directly impacting its flight characteristics. This guide breaks down the wing construction process, covering ribs, spars, leading/trailing edges, and applying the covering material. We're focusing on a simple design, so we’re emphasizing clarity and ease of construction.

Understanding the Key Components

Before we begin, let's define our terms:

- Ribs: These are the internal structures that give the wing its airfoil shape. They're like the “bones” of the wing.

- Spars: Spars run the length of the wing and provide strength and rigidity, preventing the wing from twisting or bending excessively.

- Leading Edge: This is the front edge of the wing that first encounters the airflow.

- Trailing Edge: This is the back edge of the wing.

- Covering: This is the material (typically lightweight film) that gives the wing its final shape and aerodynamic surface.

Building the Ribs

For a simple design, the ribs are often made from balsa wood. You can either buy pre-cut ribs, which simplifies the process, or cut them yourself using a template. Accuracy is key here. Inaccurate rib shapes will result in an uneven and poorly performing wing.

If Cutting Your Own Ribs:

- Create a rib template. This can be drawn on cardboard or printed from a plan.

- Use a hobby knife to carefully cut the ribs from thin balsa sheets (1/16" or 1/8" thickness is common).

- Ensure all ribs are identical. Small discrepancies can negatively affect the wing's flight characteristics.

Constructing the Spars

Spars are the primary structural elements of the wing. They run the entire length of the wing, typically one or two spars are used. These spars are also typically made from balsa wood, but a stronger type (rectangular or square cross-section) is preferred. Securely attaching the ribs to the spars is crucial for the wing's strength.

Attaching Ribs to Spars:

- Use a lightweight wood glue (CA glue or aliphatic resin) for attaching the ribs to the spars.

- Ensure the ribs are perpendicular to the spars and correctly positioned according to your plans.

- Use jigs or temporary supports to hold the ribs in place while the glue dries.

Leading and Trailing Edges

The leading and trailing edges contribute to the wing's shape and aerodynamics. These are typically made from balsa wood, slightly larger in cross-section than the ribs. They are glued to the ribs and spars, forming the outer perimeter of the wing.

Applying the Covering

Once the wing structure is complete, it's time to apply the covering. Lightweight heat-shrink film is commonly used. This material provides a smooth, aerodynamic surface and adds strength to the wing.

Covering Steps:

- Cut the covering material slightly larger than the wing surface.

- Use a covering iron (or a regular iron with a protective layer) to gently heat the film.

- The heat causes the film to shrink and conform to the wing’s shape.

- Use a covering iron's rollers to smooth the surface and remove any wrinkles or bubbles.

- Trim any excess covering material.

Final Thoughts

Wing construction is a vital part of building your RC airplane. Take your time, pay attention to detail, and follow your plans carefully. A well-constructed wing will contribute to a stable and enjoyable flying experience. Remember to always prioritize safety and double-check your work.